April is Cannabis Awareness Month! Did you know Truro is home to a state-of-the-art, internationally-known cannabis growing facility? Whether you use cannabis or not, the process of producing cannabis at a mass scale is fascinating and worth learning about. And if you are a cannabis consumer, remember to support local! Truro Cannabis products are available at most NSLC locations. We were invited to tour their facility to spread awareness of what goes into their production and to learn more about how cannabis is grown in Truro.

Truro Cannabis is a nexus of science, engineering, and passion. They strive to grow the best cultivars and to put only the best products into the market. Truro Cannabis is planning to release a new cultivar strain every quarter to give consumers more variety.

Their production “line” is a mix of science lab, indoor cultivation, and high-tech manufacturing facility. We were given a tour of their facility earlier this month and learned so much about what it takes to grow high-quality, safety-tested cannabis at a grand scale.

First and foremost, they take safety very seriously, both for their employees and their consumers. As soon as you enter the facility, it is clear that they are vigilant about any and all risks to people and plants.

To ensure that these risks are mitigated, Truro Cannabis takes a science-based approach. The air into and out of the facility is filtered to an impressive degree, with an “air shower” given to everyone entering the growing space. Plant nutrition is monitored by staff via probes in the soil that can take frequent snapshots of soil quality, fertiliser amounts, and humidity of the air and the moisture in the soil. Cross-contamination is prevented by frequent sanitization of hands and tools. To be perfectly honest, everything felt hospital-clean even with soil everywhere!

Fertiliser and water are precisely controlled to ensure that each plant remains healthy and that the end product is consistent with the highest consumer expectations. A healthy plant will make a safer end-product and consistent quality means the consumer knows what to expect which allows them to make the safest decisions about their own cannabis use.

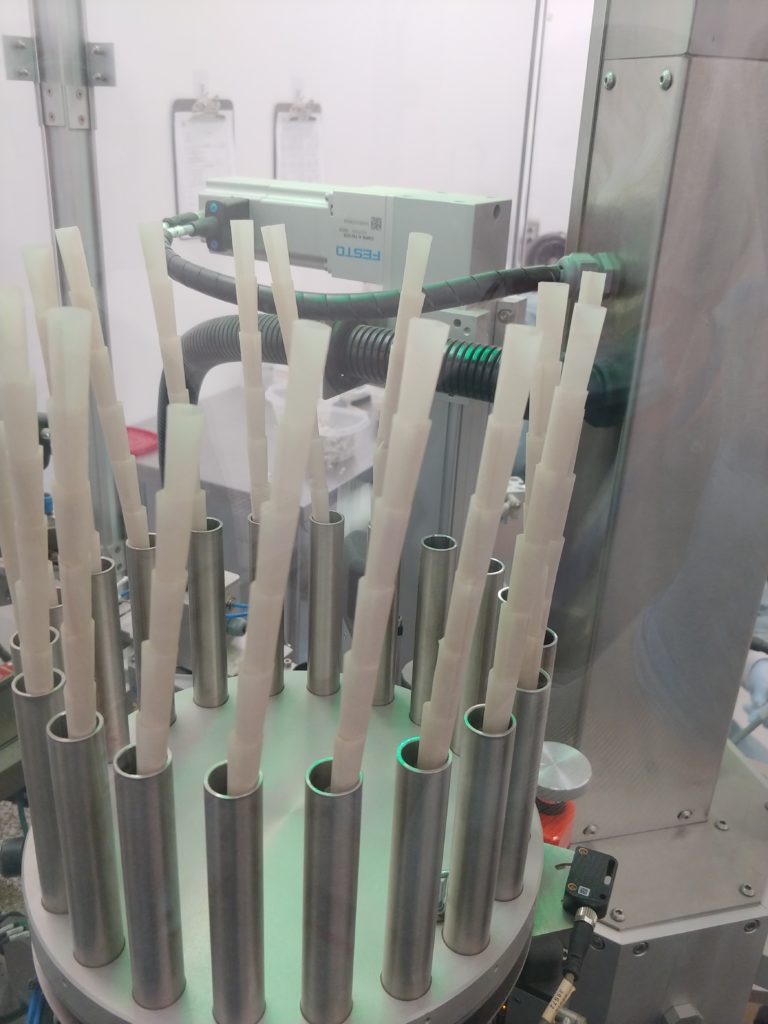

Another way Truro Cannabis ensures safety is with their packaging. The machine used to create pre-rolled cannabis products is built to precisely measure the weight of each joint, well packed into the paper tube while in an enclosed space with minimal human intervention, preventing cross-contamination or product loss or shifting.

The same goes for loose product. The cans are built with safety and accessibility as the main focus. The lids have been tested and given the rating of child resistant and senior friendly. The use of liquid nitrogen allows for stabilization of the product from the packaging room to the end user, ensuring moisture levels are correct and to stop any terpene degradation. This is done by displacing oxygens levels down to 3% to 4% from the normal 21% in the air we breathe.

Plant care is another huge focus of Truro Cannabis. I mentioned the precise control of fertilizer and moisture above; however plant care is so much more than that. From genetics and cloning for plant propagation, to monitoring growth rates and flower development, all plants grown by their team are cared for like the most spoiled houseplants you can imagine.

Cannabis plants that are grown in large quantities for sale to the public aren’t grown from seed. In a method that may be familiar to house plant collectors, they are cloned from a mother plant and propagated. This means that each plant of a specific strain from Truro Cannabis is genetically identical to the mother plant and to each other. A piece of the mother plant is trimmed off and placed in a rooting medium with rooting hormone. Once the roots reach a certain size, the propagating piece is transplanted into soil and repotted several times as it grows larger

Plants have very predictable growing schedules, thanks to the precise control of fertilizer, water, and light. By constantly monitoring the triggers for growth and paying incredibly close attention to the plants themselves, these plants grow fast. There are 3 stages of growth for plants that are destined for consumption, propagation is 7 to 14 days, vegetation is 10 to 14 days, flowering is 56 to 84 days. Depending on the strain that is growing some have longer vegetation and flowering times, while others have shorter times.

Once plants have flowered, they are trimmed, dried and cured. Hang drying takes 10 to 14 days, curing takes 21 days. Truro Cannabis believes this is necessary to have the best product for the end consumer. Their philosophy is “low and slow” meaning they take the time to use lower temperatures and longer curing and hanging times to ensure the product is at its best.

Hang drying the product removes 60% to 75% of the water in cannabis. Curing allows the additional moisture to slowly leave the plant and allows for off-gassing of unwanted vapours and flavours from the product, allowing the terpenes to become more pronounced.

The quality of cannabis greatly differs between licensed producers and home-growers. LPs are a regulated source that has to go through a microscope of testing to ensure the final product meets Health Canada standards. Tests for everything including heavy metals, pesticides, moulds, yeast, micro bacteria and such are all held to an extremely high standard, compared to no standards or testing in other markets.

Truro Cannabis may take a very serious scientific approach to plant care and production but everyone we met on our visit was clearly doing so because they are passionate about the product they create. They were open, friendly and proud of what they have developed and grown in our community. Their facility was impressive, with quality and safety at the center of everything they do.